Sabuk konveyor multi-judul diterapkan secara luas untuk menyampaikan material di bidang tambang, pelabuhan, metalurgi. Ada banyak jenis jenis serat seperti poliester, kapas, terilen, poliamida, monofilamen, dan kami terutama menggunakan nilon (poliamida), sabuk jenis poliester EP. Mohon spesifikasi berikut

|

Tekstil Barang |

Struktur |

Tekstil Barang |

Ketebalan |

Kekuatan Tarik (N / M) |

Ketebalan karet penutup (mm) |

Rentang Lebar (mm) |

|||||

|

Melengkung |

Pakan |

2Ply |

3ply |

4ply |

5ply |

6ply |

|||||

|

NN |

Nilon |

Nilon |

Nn100 |

1 |

200 |

300 |

400 |

500 |

600 |

300-2500 |

≤300 |

|

Nn125 |

1 |

250 |

375 |

500 |

625 |

750 |

300-2500 |

≤300 |

|||

|

Nn150 |

1.1 |

300 |

450 |

600 |

750 |

900 |

300-2500 |

≤300 |

|||

|

Nn200 |

1.2 |

400 |

600 |

800 |

1000 |

1200 |

300-2500 |

≤300 |

|||

|

Nn250 |

1.4 |

500 |

750 |

1000 |

1250 |

1500 |

300-2500 |

≤300 |

|||

|

Nn300 |

1.6 |

600 |

900 |

1200 |

1500 |

1800 |

300-2500 |

≤300 |

|||

|

Nn350 |

1.8 |

700 |

1050 |

1400 |

1750 |

2100 |

300-2500 |

≤300 |

|||

|

Nn400 |

1.9 |

800 |

1200 |

1600 |

2000 |

2400 |

300-2500 |

≤300 |

|||

|

Nn500 |

2.1 |

1000 |

1500 |

2000 |

2500 |

3000 |

300-2500 |

≤300 |

|||

|

Nn630 |

2.4 |

1260 |

1890 |

2520 |

3150 |

3780 |

300-2500 |

≤300 |

|||

|

Tekstil Barang |

Struktur |

Tekstil Barang |

Ketebalan |

Kekuatan Tarik (N / M) |

Ketebalan karet penutup (mm) |

Rentang Lebar (mm) |

|||||

|

Melengkung |

Pakan |

2Ply |

3ply |

4ply |

5ply |

6ply |

|||||

|

EP |

Poliester |

Nilon |

Nn100 |

1 |

200 |

300 |

400 |

500 |

600 |

300-2500 |

≤300 |

|

Nn125 |

1 |

250 |

375 |

500 |

625 |

750 |

300-2500 |

≤300 |

|||

|

Nn150 |

1.1 |

300 |

450 |

600 |

750 |

900 |

300-2500 |

≤300 |

|||

|

Nn200 |

1.2 |

400 |

600 |

800 |

1000 |

1200 |

300-2500 |

≤300 |

|||

|

Nn250 |

1.4 |

500 |

750 |

1000 |

1250 |

1500 |

300-2500 |

≤300 |

|||

|

Nn300 |

1.6 |

600 |

900 |

1200 |

1500 |

1800 |

300-2500 |

≤300 |

|||

|

Nn350 |

1.8 |

700 |

1050 |

1400 |

1750 |

2100 |

300-2500 |

≤300 |

|||

|

Nn400 |

1.9 |

800 |

1200 |

1600 |

2000 |

2400 |

300-2500 |

≤300 |

|||

|

Nn500 |

2.1 |

1000 |

1500 |

2000 |

2500 |

3000 |

300-2500 |

≤300 |

|||

|

Nn630 |

2.4 |

1260 |

1890 |

2520 |

3150 |

3780 |

300-2500 |

≤300 |

|||

Pemilihan model kain

| Item Tekstil | Struktur | Diameter drum sesuai dengan jumlah lapisan kain (mm) | |||||

| 2 | 3 | 4 | 5 | 6 | 7 | ||

| EP | EP200 | 200 | 250 | 315 | 400 | 500 | 630 |

| EP125 | 200 | 250 | 315 | 400 | 630 | 800 | |

| EP150 | 250 | 315 | 400 | 630 | 800 | 1000 | |

| EP200 | 315 | 500 | 630 | 800 | 1000 | 1250 | |

| EP250 | 400 | 630 | 800 | 1000 | 1250 | 1400 | |

| EP300 | 500 | 630 | 800 | 1000 | 1250 | 1400 | |

| NN | NN100 | 200 | 250 | 315 | 400 | 500 | 630 |

| NN125 | 200 | 250 | 315 | 400 | 500 | 630 | |

| NN150 | 200 | 250 | 315 | 400 | 500 | 630 | |

| NN200 | 250 | 315 | 400 | 500 | 630 | 800 | |

| NN250 | 315 | 400 | 500 | 630 | 800 | 1000 | |

| NN300 | 400 | 500 | 630 | 800 | 1000 | 1250 | |

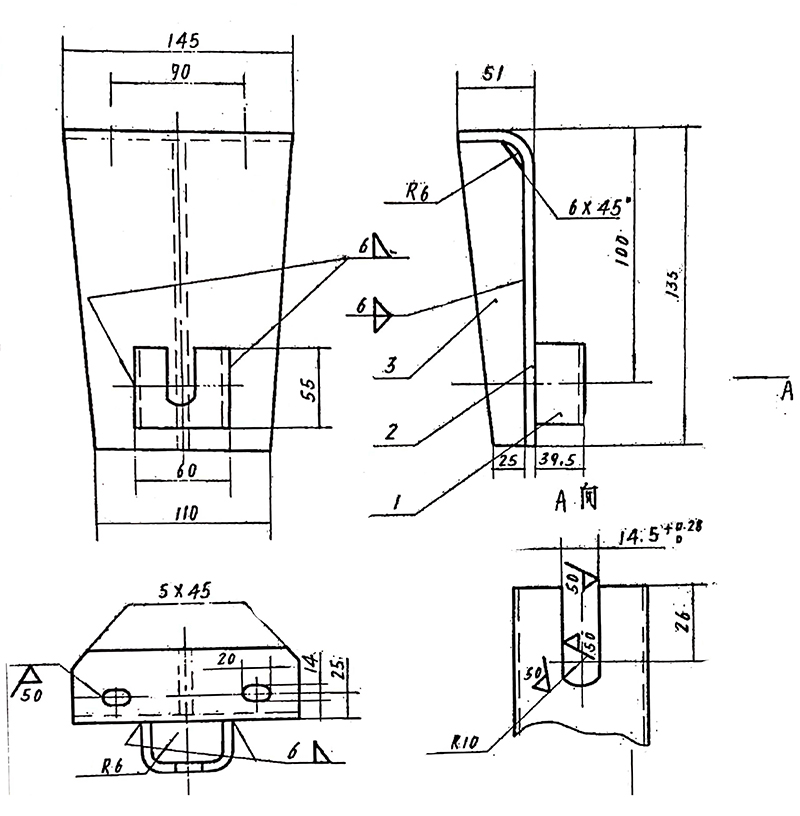

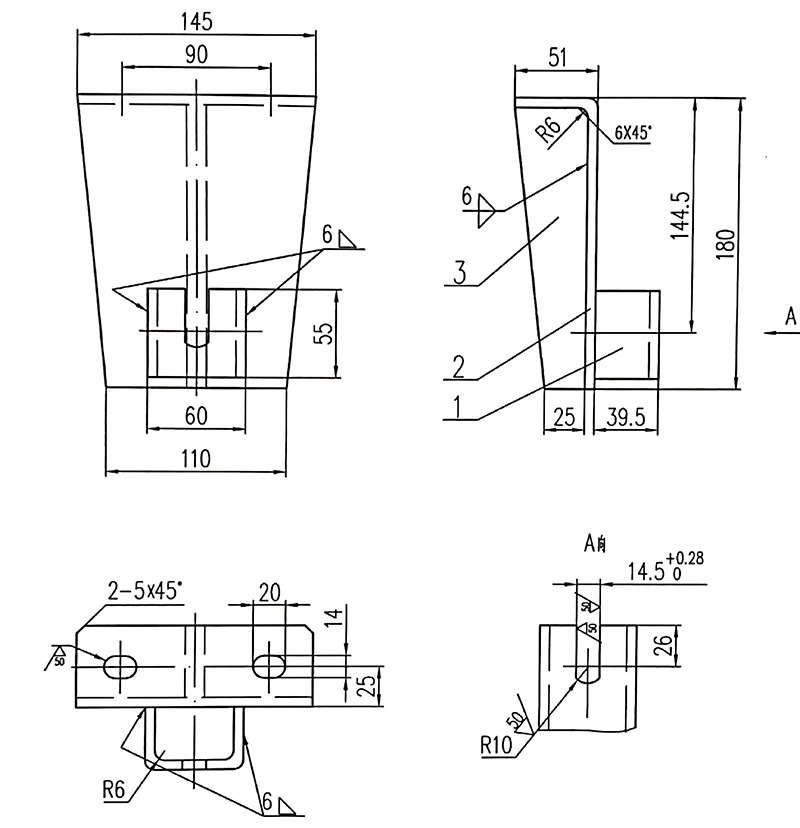

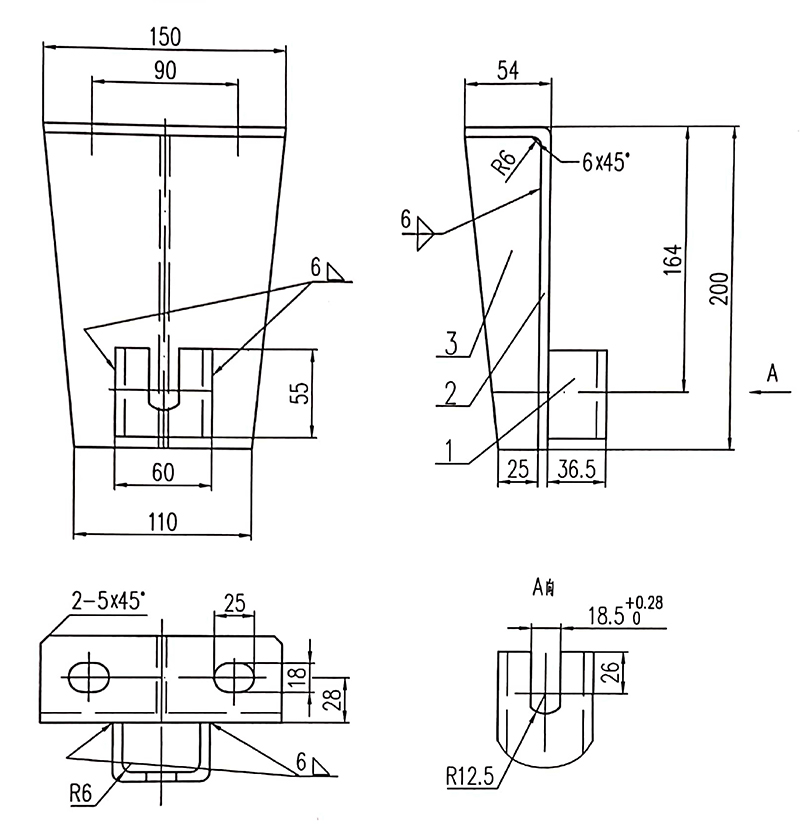

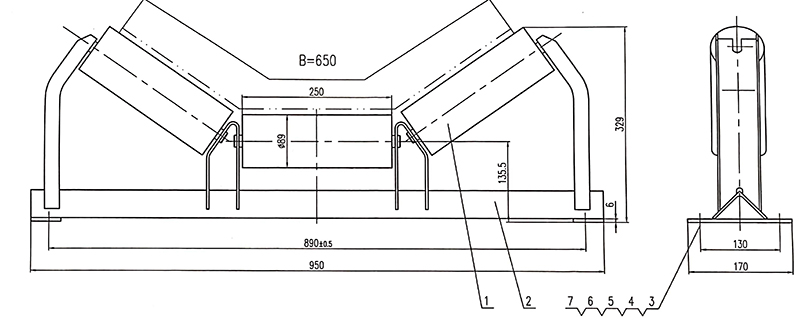

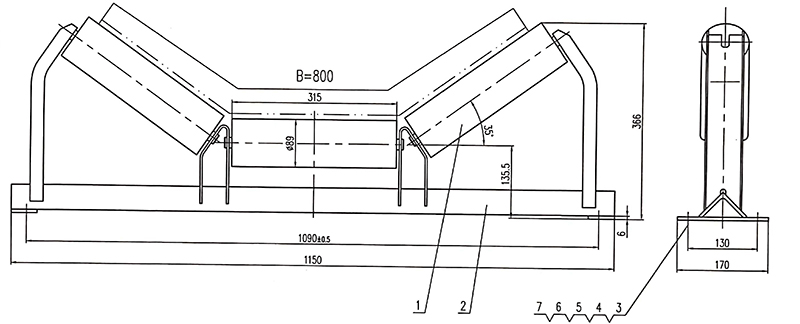

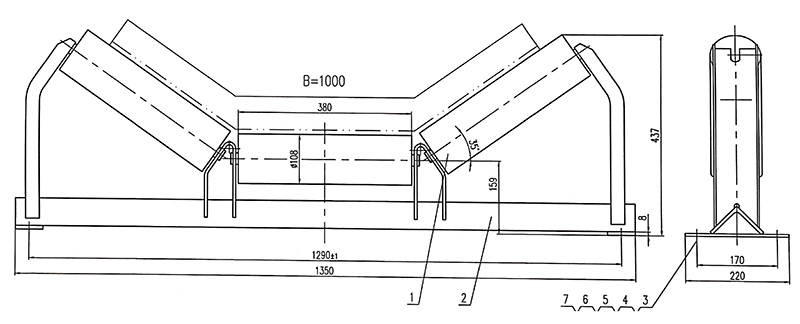

Bracket idler menggunakan pengelasan genggam, dan kemudian mengecat setelah perawatan permukaan. Itu akan memastikan ketepatan dan kekuatan idler untuk membuat pengangkatan layanan yang lama dan penampilan yang baik. Kami terutama menggunakan set roller palung TDII

B650

B800

B1000

Kembali ke roller

B650

B800

B1000

Kembali ke roller

|

Drum Dia.D (mm) |

Lebar Sabuk B (mm) |

Daya P (kW) |

Kecepatan permukaan drum V m / s |

|||||||||||

|

0.32 |

0.4 |

0,5 |

0.63 |

0.8 |

1.0 |

1.25 |

1.6 |

2.0 |

2.5 |

3.15 |

4.0 |

|||

|

Φ320 |

400/500/650/800/1000 |

2.2 / 3.0 / 4.0 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

5.5 / 7.5 |

√ |

√ |

√ |

√ |

√ |

√ |

||||||||

|

Φ400 |

400/500/650/800/1000 |

2.2 / 3.0 / 4.0 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

5.5 / 7.5 |

√ |

√ |

√ |

√ |

√ |

√ |

||||||||

|

Φ500 |

500/650/800/1000/1200 |

2.2 / 3.0 / 4.0 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

5.5 / 7.5 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

|

11/15 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

||||||

|

18.5 / 22/30/37 |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

√ |

|||

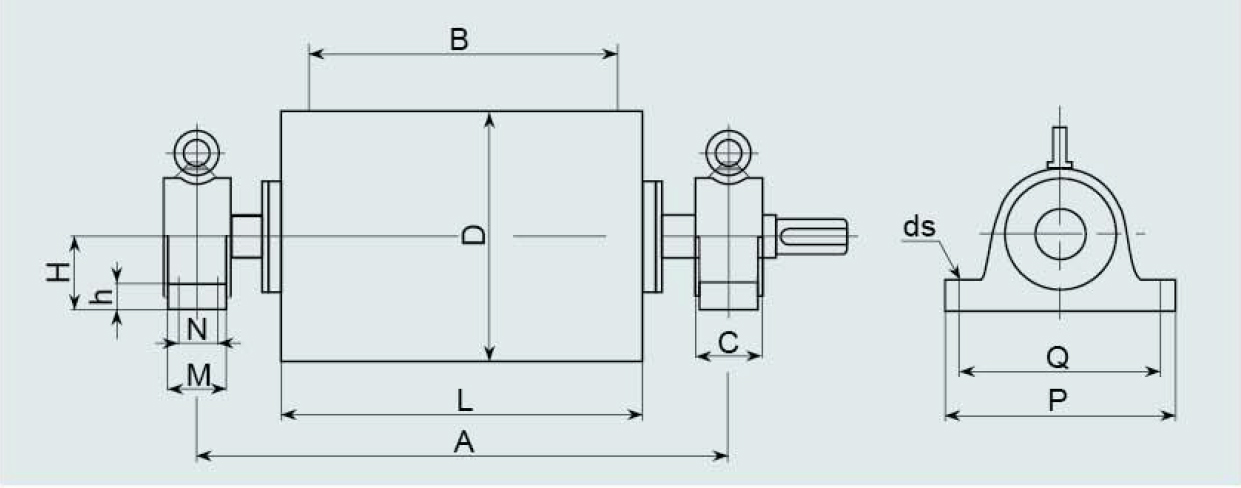

Ukuran eksternal pemasangan YTH

| D | B | SEBUAH | L | H. | C | M | N | P. | Q | H. | DS |

|

Φ320 Φ400 |

400 | 750 | 500 | 120 | 110 | 90 | - | 340 | 280 | 35 | Φ27 |

| 500 | 850 | 600 | |||||||||

| 650 | 1000 | 750 | |||||||||

| 800 | 1300 | 950 | |||||||||

| 1000 | 1500 | 1150 | |||||||||

| Φ500 | 500 | 850 | 600 | 120 | 120 | 90 | - | 340 | 280 | 35 | Φ27 |

| 650 | 1000 | 750 | |||||||||

| 800 | 1300 | 950 | |||||||||

| 1000 | 1500 | 1150 | |||||||||

| 1200 | 1750 | 1400 | |||||||||

| Φ630

Φ800 Φ1000 Φ1250 |

650 | 1000 | 750 | 120 | 120 | 90 | - | 340 | 280 | 35 | Φ27 |

| 800 | 1300 | 950 | 140 | 140 | 130 | 80 | 400 | 330 | 50 | Φ27 | |

| 1000 | 1500 | 1150 | |||||||||

| 1200 | 1750 | 1400 | 160 | 160 | 150 | 90 | 440 | 360 | 50 | Φ34 | |

| 1400 | 2000 | 1600 | |||||||||

| 1600 | 2200 | 1800 | |||||||||

| 1800 | 2400 | 2000 | |||||||||

| 2000 | 2600 | 2200 |

Drum bermotor tipe TDY berpendingin oli banyak digunakan untuk tujuan umum di Cina. Motornya dibuat oleh produsen motor khusus, tidak di bawah standar nasional seri Y pada level daya yang sama. Untuk memenuhi kebutuhan pelanggan kami, drum bermotor tipe TDY berpendingin oli akan terus diproduksi.

Daftar parameter Jenis TDY

| Dia.D drum (mm) | Daya P (kW) | Sabuk) | Kecepatan permukaan drum V (m / s) | Massa M (kg) | |||||||||||

| 0.25 | 0.32 | 0.4 | 0,5 | 0.63 | 0.8 | 1.0 | 1.25 | 1.6 | 2.0 | 2.5 | 3.15 | ||||

| Φ320 | 1.5 / 2.2 / 3 | 500/650/800/100 | △ | △ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | 130/140/160/170 | |||

| 4 / 5.5 | 500/650/800/1000 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | 170/180/200/220 | ||||||

| Φ400 | 2.2 / 3 | 500/650/800/100 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | 248/262/270/295 | ||

| 4 | 500/650/800/1000 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | 253/267/277/300 | ||||

| 5.5 / 7.5 | 650/800/100 | ○ | ○ | ○ | ○ | ○ | ○ | 273/287/297/320 | |||||||

| 11 | 800/1000 | ○ | ○ | ○ | ○ | 317/340 | |||||||||

| Φ500 | 2.2 / 3 | 500/650/800/1000 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |||

| 4 / 5.5 | 500/650/800/1000 | △ | △ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |||

| 7.5 / 11 | 650/800/1000/1200 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |||||

| 15 / 18.5 | 800/1000/1200 | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||

| 22 | 800/1000/1200 | ○ | ○ | ○ | ○ | ○ | |||||||||

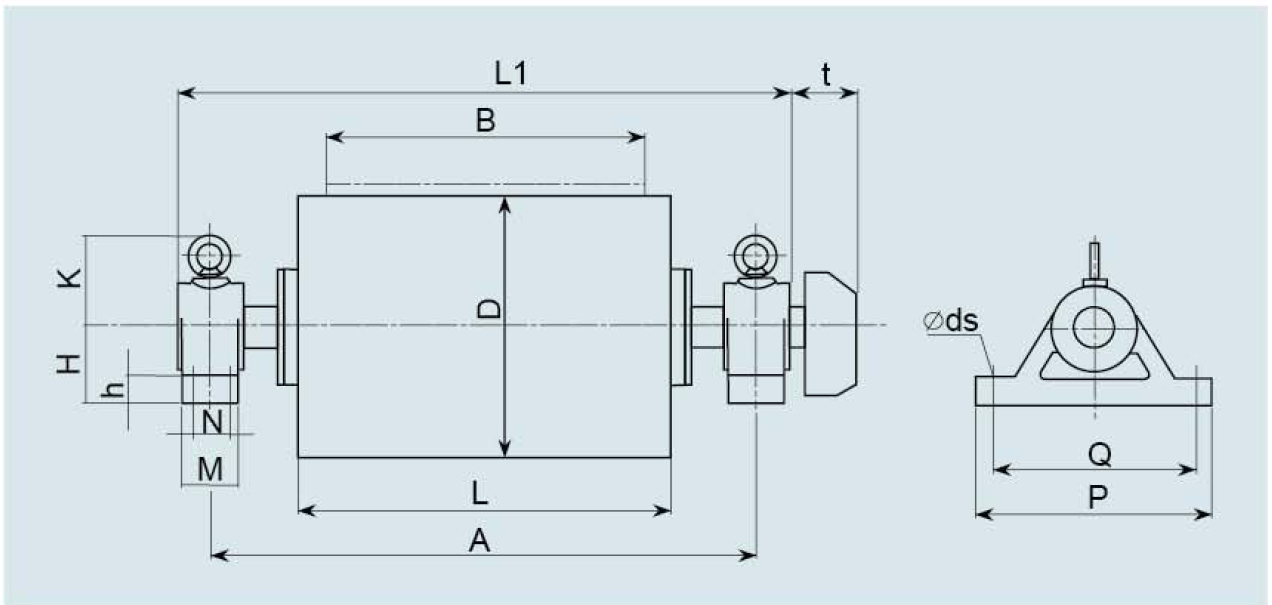

Daftar parameter Jenis TDY

| D | B | SEBUAH | L | L1 | t | H. | C | M | N | P. | Q | H. | DS |

| Φ320 | 500 | 850 | 600 | 920 | 115 | 120 | 125 | 70 | - | 340 | 280 | 35 | Φ27 |

| 650 | 1000 | 1070 | 1070 | ||||||||||

| 800 | 1300 | 1570 | 1570 | ||||||||||

| 1000 | 1500 | 1220 | 1220 | ||||||||||

| Φ400 | 500 | 850 | 600 | 940 | 1150 | 120 | 125 | 90 | - | 340 | 280 | 35 | Φ27 |

| 650 | 1000 | 1070 | 1090 | ||||||||||

| 800 | 1300 | 1570 | 1240 | ||||||||||

| 1000 | 1500 | 1220 | 1590 | ||||||||||

| Φ500 | 500 | 850 | 600 | 960 | 115 | 100 | 145 | 70 | - | 340 | 280 | 35 | Φ27 |

| 620 | |||||||||||||

| 650 | 1000 | 750 | 1120 | 120 | 90 | ||||||||

| 800 | 1300 | 950 | 1420 | ||||||||||

| 1000 | 1500 | 1150 | 1620 | ||||||||||

| 1200 | 1750 | 1400 | 1870 | ||||||||||

| Φ630

Φ800 |

650 | 1000 | 750 | 1120 | 115 | 120 | 175 | 90 | - | 340 | 280 | 35 | Φ27 |

| 800 | 1300 | 950 | 1430 | 140 | 130 | 80 | 400 | 330 | 35 | Φ27 | |||

| 1000 | 1500 | 1150 | 1630 | ||||||||||

| 1200 | 1750 | 1400 | 1900 | 160 | 180 | 150 | 90 | 440 | 360 | 50 | Φ34 | ||

| 1400 | 2000 | 1600 | 2150 | ||||||||||

| 1600 | 2200 | 1800 | 2350 |